Last week we discussed 9 major patterns every man should know. Today we will explore dress shirt fabrics. Understanding the difference between some of these fabrics will not only help you flex your sartorial intellect but allow you to find the ideal dress shirt fabric for your needs.

Also check out our new Gotstyle Launch program which features a line of dress shirts, trousers, suits and leather shoes. Everything you need to build your wardrobe.

Before we break down the 10 major dress shirt fabrics, it is important to point out the fundamentals of what makes a great fabric.

Step one: Identifying the core: is it cotton, man-made fibers or silk? Ideally, you want to stick with cotton as it is the undisputed king of dress shirt fabrics. A finely woven cotton fabric has all the properties a man could want from a garment worn close to the body: good heat and moisture conduction, durability, smoothness, and the ability to take shape when ironed.

Man-made fibers, on the other hand, don’t offer the same comfort as a cotton shirt but do have their own set of advantages. They are often wrinkle and stain resistant and can be ideal for budget minded individuals. Lastly, there is silk, often associated as a luxury fabric, silk offers that high sheen and light drape. It is great for bathrobes and boxers shorts but not necessarily for a shirt. The maintenance costs are high and long term durability low.

Step two: Know your ply. Ply is how many yarns are twisted together to make a single thread. Dress shirt fabrics are most often two-ply or single ply. Two-ply fabrics are generally superior to single-ply fabrics.

Step three: The count. Thread count indicates the size of the thread in the fabric and therefore how many threads per square inch and is often referred to with a number like 50s, 80s, 100s, 120s, 140s 160s, etc up to 200s. For example, 140s means there are 140 hanks (1 hank = 840 yards) of yarn in one pound. Higher numbers mean that the threads are finer which results in a softer, smoother and lighter fabric.

Step four: The finish. Often overlooked, the finish of the fabric is the production process used to actually mill the fabric. A 2-ply 200s fabric sounds impressive but if it’s made with low quality cotton by a dubious manufacturer then it is no better and probably worse than a 1-ply 50s fabric made by a reputable mill.

10 Dress Shirt Fabrics

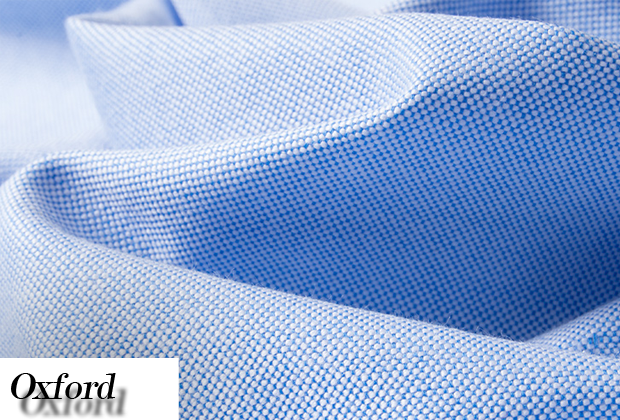

- Similar to pinpoint oxford- slightly heavier thread and looser weave

- Slightly rougher texture but is more durable than most fabrics

- Symmetrical basket weave where one yarn may cross two yarns

- Originally developed for sports, the oxford shirt is great as a casual button down shirt

- Woven fabric produced on the dobby loom

- Characterised by small geometric patterns and extra texture in the cloth

- Very similar to Jacquard, although technically different

- Many dobby fabrics have stripes woven into them, although some are solid colors

- The solid colors tend to have a faint stripe or dotted patterns woven in the same color as the base cloth

- A sturdy cotton twill textile- possibly coarser twill.

- Typically softer, lighter versions of the fabric then that of your jeans

- Great for casual wear

- A plain weave fabric with a colored warp and a white weft

- Generally made with heavier yarns for a rugged, blue-collar workwear appeal

- Great for casual wear

- A dense, plain woven cloth, historically made of wool

- A tightly woven fabric with a very simple over-under weave and slight sheen

- Great for dressy occasions

- Highly weatherproof and hard wearing

- Is a soft woven fabric, of various fineness

- Typically fuzzy in feel otherwise known as brushed twill or brushed melange

- Great for cooler weather like Fall/Winter

- Ideal for casual wear

- Special type of construction in which each yarn is a combination of fibers that are dyed and not-dyed

- Generally very thin and very smooth luxurious fabrics with a particular soft finish

- These different colored cotton fibers are woven together for a feathered, intentionally inconsistent, somewhat organic look.

- Pinpoint (also referred to as pinpoint oxford) has a similar weave as oxford cloth but uses a finer yarn and tighter weave

- More formal than oxford cloth, but less formal than broadcloth

- Pinpoint fabrics are generally not transparent and are slightly heavier and thicker than broadcloths

- Great choice for business shirts

- Made from a plain weave of fine yarns, creating a thin, soft, smooth, long-lasting fabric

- Thin and breathable – great for under jackets or blazers

- Can be slightly transparent due to it’s thinness

- Does well with retaining smoothness after being ironed

- Sometimes described as broadcloth (technically different, but pretty much the same)

- Distinctive diagonal weave

- Soft, and a bit thicker and warmer than poplin

- Has a tendency to wrinkle easily for some

- Works under a jacket, but not quite as breathable as poplin

- Seems to be difficult to remove stains from twill